Introduction

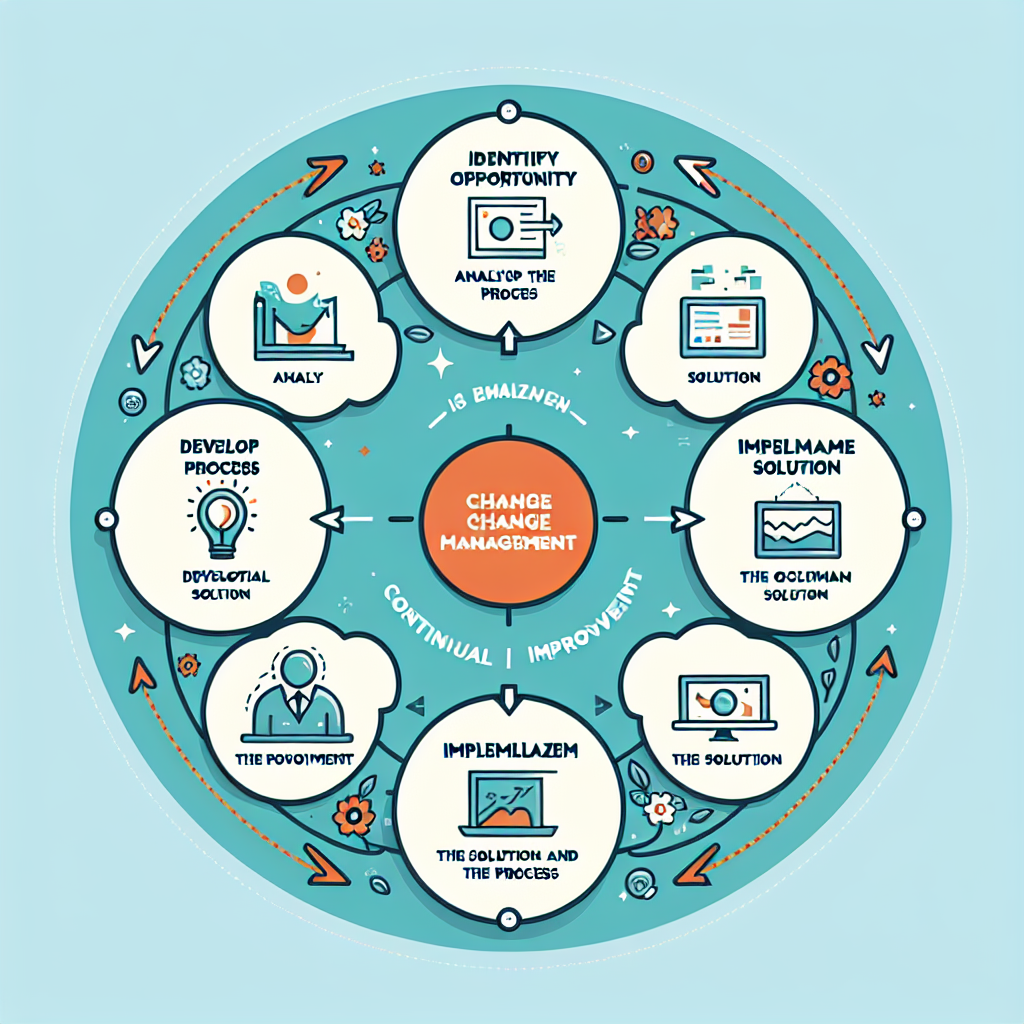

The business landscape is constantly evolving, driven by technological advancements, shifting consumer expectations, and competitive pressures. Organizations that can adapt quickly and efficiently have a significant advantage. Change management models are crucial in guiding businesses through this adaptation process, ensuring smooth transitions and long-term success. One such highly regarded model is the KAIZEN Change Management Model, which emphasizes continuous, incremental improvements rather than radical, sweeping changes. Originating from Japan, the KAIZEN philosophy has become a cornerstone for businesses aiming to foster innovation, improve efficiency, and build a culture of sustained improvement.

This essay explores the fundamental concepts of the KAIZEN model, its application in modern organizations, and the benefits it offers compared to more traditional change management approaches.

Understanding KAIZEN

KAIZEN, a Japanese term meaning “change for the better” or “continuous improvement,” was developed as part of Japan’s post-World War II industrial recovery. Popularized by companies like Toyota, KAIZEN is both a philosophy and a practical methodology that encourages incremental, continuous improvement at every level of an organization, from executives to factory workers.

Unlike other change management models that rely on large-scale, disruptive transformations, KAIZEN advocates for small, manageable changes implemented regularly over time. This fosters a culture where employees are empowered to identify inefficiencies and take ownership of improving their work processes.

The KAIZEN model is often implemented through small teams working on specific projects aimed at streamlining processes, enhancing product quality, reducing waste, or increasing customer satisfaction. These teams regularly analyze their work, suggest improvements, and track their outcomes. The emphasis on teamwork and cross-departmental collaboration makes KAIZEN particularly effective in creating lasting change.

Core Principles of the KAIZEN Model

Continuous Improvement: The essence of KAIZEN lies in its commitment to constant, incremental changes. The philosophy discourages complacency by encouraging all employees to contribute ideas for improvements, however small. This results in steady progress that cumulatively leads to significant enhancements over time.

Employee Involvement: KAIZEN promotes a culture where all employees, regardless of rank or department, participate in the improvement process. Workers on the ground are often the ones closest to the issues and are best positioned to identify potential solutions. Empowering employees to suggest and implement changes fosters ownership and accountability.

Focus on Processes: KAIZEN emphasizes improving the processes rather than focusing solely on outcomes. By analyzing how tasks are performed and identifying inefficiencies, organizations can make lasting improvements that boost productivity and quality.

Waste Reduction (Muda): One of the key goals of the KAIZEN model is to eliminate waste—whether it’s time, materials, or effort. The Japanese term for waste, Muda, plays a central role in KAIZEN initiatives, which focus on streamlining operations to make them as efficient as possible.

Standardization: Once improvements are made, KAIZEN encourages standardizing the improved process. This ensures that the gains made are not temporary and can be consistently applied across the organization. After standardization, the cycle of continuous improvement begins again, allowing the organization to build on its successes.

Quality Circles: An integral aspect of KAIZEN is the use of quality circles—small groups of employees who meet regularly to discuss improvements. These teams play a key role in identifying areas for change, suggesting solutions, and implementing those changes. They also help in creating a feedback loop that sustains ongoing improvements.

The KAIZEN Cycle: PDCA (Plan-Do-Check-Act)

The KAIZEN model uses the PDCA cycle, also known as the Deming Cycle, to guide improvement initiatives. This structured approach ensures that every change is carefully planned, implemented, evaluated, and standardized.

Plan: Identify a process that requires improvement and develop a detailed plan to address inefficiencies. This stage involves gathering data, defining objectives, and preparing for implementation.

Do: Implement the proposed changes on a small scale, testing them in a controlled environment to gauge their effectiveness.

Check: Analyze the results of the implementation, comparing them to the expected outcomes. If the changes yield positive results, move on to the next step; if not, revise the plan accordingly.

Act: Once the changes are proven successful, implement them on a larger scale and standardize the new process. This phase also includes documenting the process for future reference and ensuring that the improvements become embedded in the organization’s workflows.

This iterative cycle ensures that change is not only incremental but also sustainable. The PDCA process can be repeated indefinitely, driving continuous improvement in all areas of the business.

Benefits of the KAIZEN Change Management Model

Sustainable Long-Term Change: Because KAIZEN focuses on gradual, small improvements rather than disruptive, large-scale overhauls, it fosters a culture of sustainability. Employees can adapt more easily to smaller changes, reducing resistance and ensuring that improvements are maintained over time.

Employee Empowerment and Engagement: By involving employees at every level of the organization, KAIZEN builds a sense of ownership and responsibility. Workers feel more engaged when they are active participants in the change process, leading to higher morale and productivity.

Improved Efficiency and Reduced Waste: The emphasis on identifying inefficiencies and eliminating waste leads to leaner operations, which can have a significant impact on cost reduction, resource utilization, and overall productivity.

Enhanced Quality and Customer Satisfaction: Continuous process improvements help organizations meet or exceed quality standards, leading to higher customer satisfaction. By focusing on refining processes rather than solely on outcomes, businesses can deliver better products and services.

Adaptability and Innovation: KAIZEN encourages constant reevaluation of processes, which makes organizations more adaptable to changing market conditions and more innovative in their problem-solving approaches.

Comparison with Other Change Management Models

Unlike traditional change management models like Lewin’s Change Model or Kotter’s Eight-Step Process, which focus on preparing for and managing specific, often large-scale change initiatives, KAIZEN is more about creating an organizational mindset geared toward continuous improvement. While other models may be more appropriate for handling significant, one-off transformations, KAIZEN excels in fostering long-term adaptability and resilience through ongoing, incremental changes.

For example, Kotter’s model emphasizes creating urgency and building momentum for large changes, while KAIZEN focuses on maintaining a steady pace of improvement without the need for major disruptions. This makes KAIZEN particularly suitable for organizations that operate in stable environments but seek continuous enhancement to stay competitive.

Conclusion

The KAIZEN Change Management Model offers a practical and sustainable approach to organizational improvement. Its core principles of continuous improvement, employee involvement, process focus, and waste reduction provide a foundation for building a culture of innovation and efficiency. By empowering employees to participate actively in the improvement process and by using structured tools like the PDCA cycle, organizations can achieve long-term success.

In an increasingly dynamic business environment, the ability to adapt and improve continuously is invaluable. The KAIZEN model not only helps organizations remain competitive but also fosters a positive workplace culture, where employees feel empowered to drive change and contribute to the organization’s success.